FAQ

Questions you might want to know

What is roofing welding?

Roofing welding is the process of joining

thermoplastic roofing membranes, such as TPO, PVC, and EPDM, using hot air and

pressure to create a strong, watertight, and durable bond.

What are the main types of roofing welding?

Hot Air Welding: Uses a roofing welder to

apply high heat and pressure for seamless bonding.

Solvent Welding: Uses chemical solvents to

soften and bond roofing materials.

Adhesive Bonding: Uses specialized

adhesives (not technically welding) to join roofing sheets.

What equipment is needed for roofingwelding?

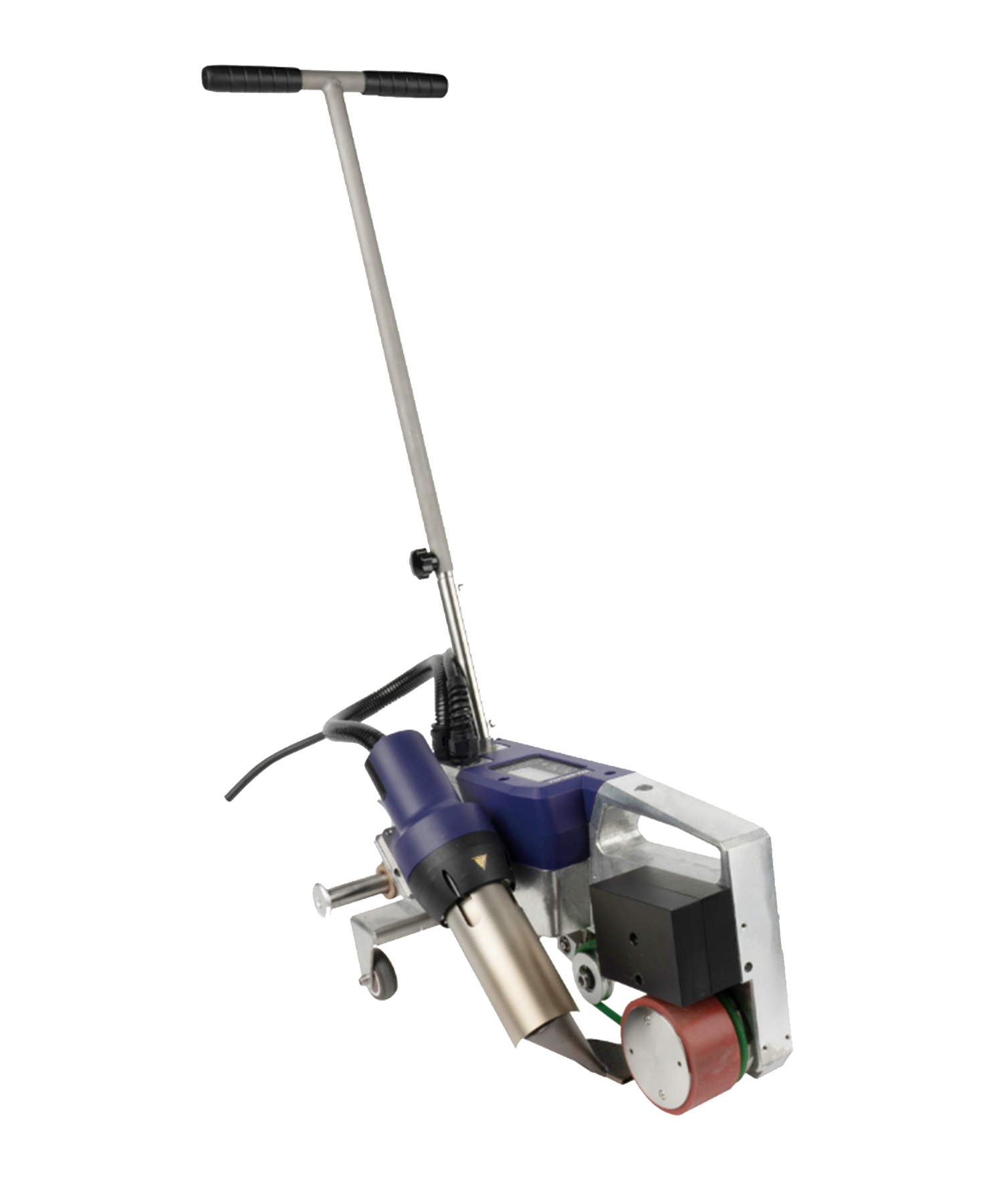

Automatic Roofing Welder: Used for large

area welding to improve welding efficiency and quality.

Hot Air Hand Tool: Suitable for detail

welding and small area repairs.

Pressure Roller: Ensures a firm bond

between the seams during welding.

Generator: Provides power for the

equipment, especially for outdoor work.