Roof welding robots are the result of the integration of automated welding technology with the demands of the construction industry. Their development has evolved from adaptations of industrial robots to specialized construction equipment, and further into intelligent systems. This article provides a detailed overview of their technological progression, key breakthroughs, and future trends.

Early Exploration Phase (1980-2000): The Initial Use of Industrial Robots

Automated welding was first applied in automotive manufacturing and heavy machinery industries. In the 1970s, Japan’s Kawasaki Heavy Industries introduced Unimate, the world’s first commercial welding robot, primarily used for spot and arc welding in automotive production lines. However, progress in construction welding automation was slow due to:

Poor Environmental Adaptability: Construction sites are complex, and traditional industrial robots could not withstand outdoor conditions like wind, rain, or dust.

Mobility Limitations: Roof work requires robots with climbing or suspension capabilities, but early robots were mostly fixed robotic arms.

By the 1990s, Europe and Japan began experimenting with welding robots in construction. For example, Germany’s KUKA and Sweden’s ABB developed rail-based welding systems for beam-column welding in large steel structure factories. However, these devices still relied on manual positioning and could not operate stably on sloped or curved roofs.

Specialized Development Phase (2000-2015): Initial Applications in Construction Welding

Entering the 21st century, the growing demand for automation in construction drove the development of specialized welding robots. Key breakthroughs during this phase included:

1. Emergence of Mobile Welding Robots

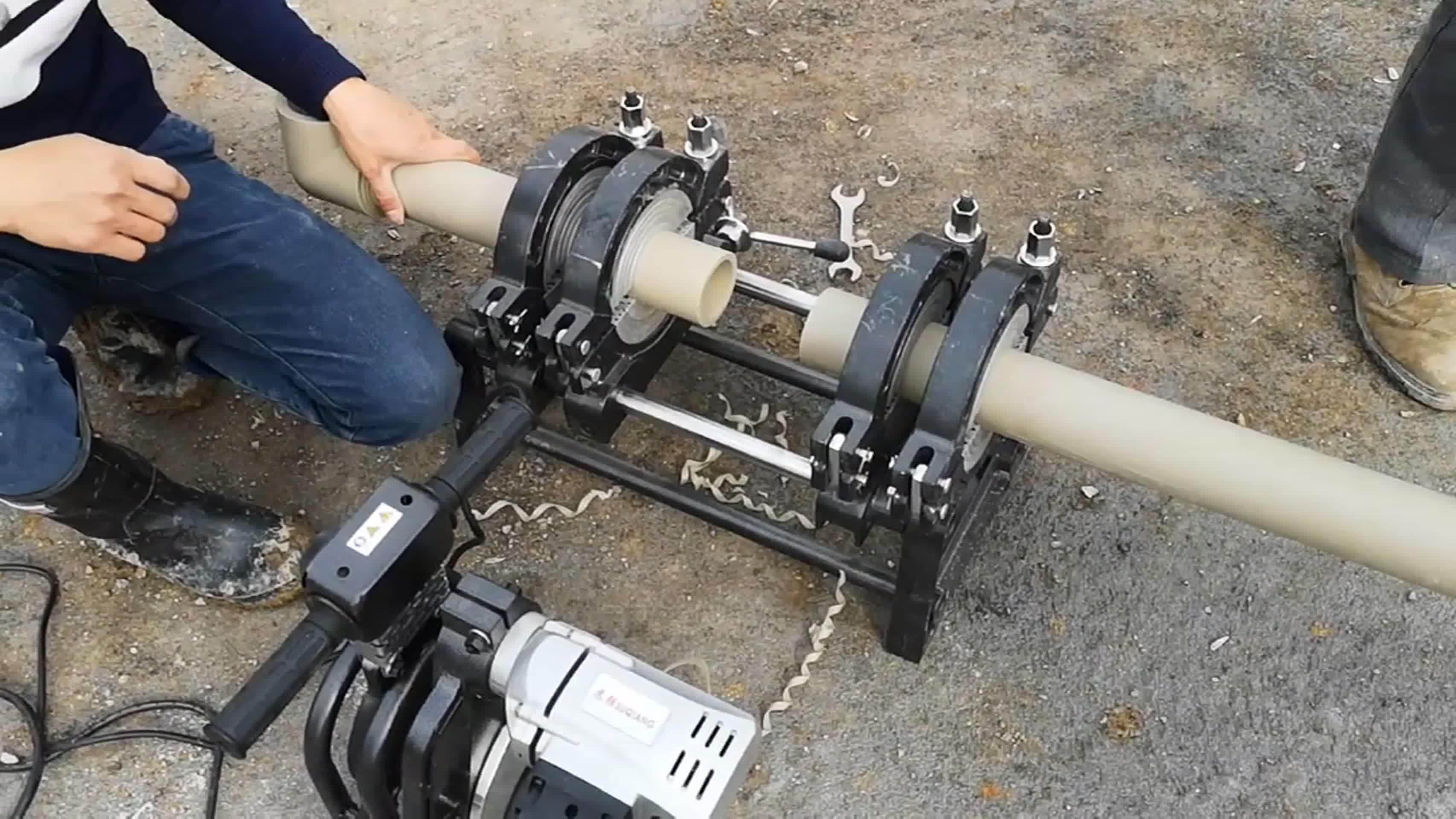

- Magnetic Climbing Robots: Companies like Germany’s Cloos and Japan’s FANUC introduced magnetic welding robots that could adhere to steel roof surfaces for automated welding, suitable for large-scale steel plate splicing.

- Rail-Based Systems: Some companies adopted rail-guided systems, allowing robots to weld along predetermined paths, though flexibility remained limited and applicable only to standardized structures.

2. Role of Building Information Modeling (BIM)

After 2010, the adoption of BIM technology enabled more precise welding path planning. Robots could adjust welding parameters automatically based on 3D model data, reducing manual intervention.

However, robots in this phase still had limitations:

- Dependence on Manual Assistance: Tasks like initial positioning and weld inspection still required worker involvement.

- Limited Adaptability: Complex roof structures (e.g., curved surfaces, multi-angle joints) remained challenging.

Intelligent Breakthrough Phase (2015-Present): The Rise of Autonomous Welding Robots

After 2015, advancements in artificial intelligence (AI), computer vision, and SLAM (Simultaneous Localization and Mapping) technologies propelled roof welding robots toward intelligence. Notable developments included:

1. Vision Navigation and Autonomous Welding

2018: The U.S.’s Sarcos Robotics launched the Guardian S, a robot equipped with high-precision vision systems capable of autonomous movement and welding on sloped roofs.

2020: China’s Baosteel and Harbin Institute of Technology jointly developed a photovoltaic roof welding robot that used laser tracking for high-precision weld positioning.

2022: Germany’s Hilti released Jaibot, a semi-autonomous welding robot designed for steel structure roofs, capable of receiving BIM data via the cloud.

2. Anti-Interference and Stability Enhancements

Wind-Resistant Stabilization Systems: New robots employed dynamic balance algorithms to ensure stable welding despite outdoor wind interference.

Multi-Sensor Fusion: Integration of laser ranging, infrared thermal imaging, and ultrasonic detection allowed real-time adjustment of welding parameters to avoid weak or excessive welds.

3. 5G and Remote Control

Recent advancements in low-latency 5G communication enabled remote-controlled welding robots. Workers could monitor the welding process in real-time via VR devices and intervene manually for complex joints.

Current Challenges and Future Trends

Despite significant technological progress, roof welding robots still face challenges:

High Costs: Premium models range from 100,000 to 100,000to300,000, making them unaffordable for many small and medium-sized enterprises.

Adaptability to Complex Scenarios: Irregular roofs and multi-material welding (e.g., steel-aluminum combinations) require further algorithm optimization.

Future Development Directions

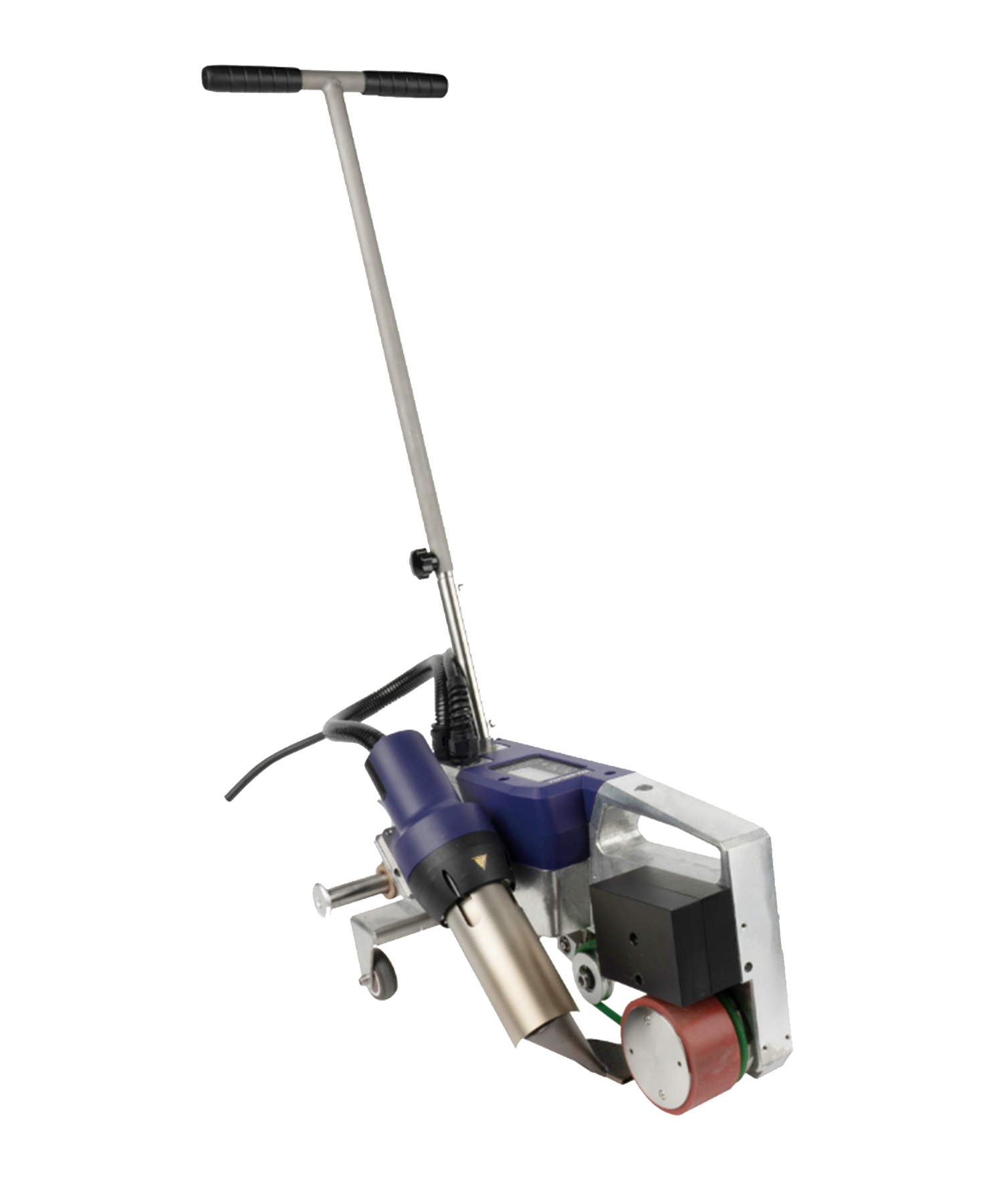

Drone-Assisted Welding: Research institutions are testing drones equipped with micro-welding torches for high-altitude, confined-space operations.

AI-Driven Decision-Making: Deep learning could enable robots to autonomously identify weld defects and perform real-time repairs.

Modular Design: Future robots may feature interchangeable welding heads to adapt to diverse construction needs.

Conclusion

The development of roof welding robots has evolved from industrial adaptations to specialized construction tools and, ultimately, intelligent autonomous systems. With advancements in AI, 5G, and new materials, these robots are expected to become standard equipment in the construction industry within the next decade, significantly improving efficiency and safety. However, reducing costs and enhancing adaptability remain critical for widespread adoption.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.