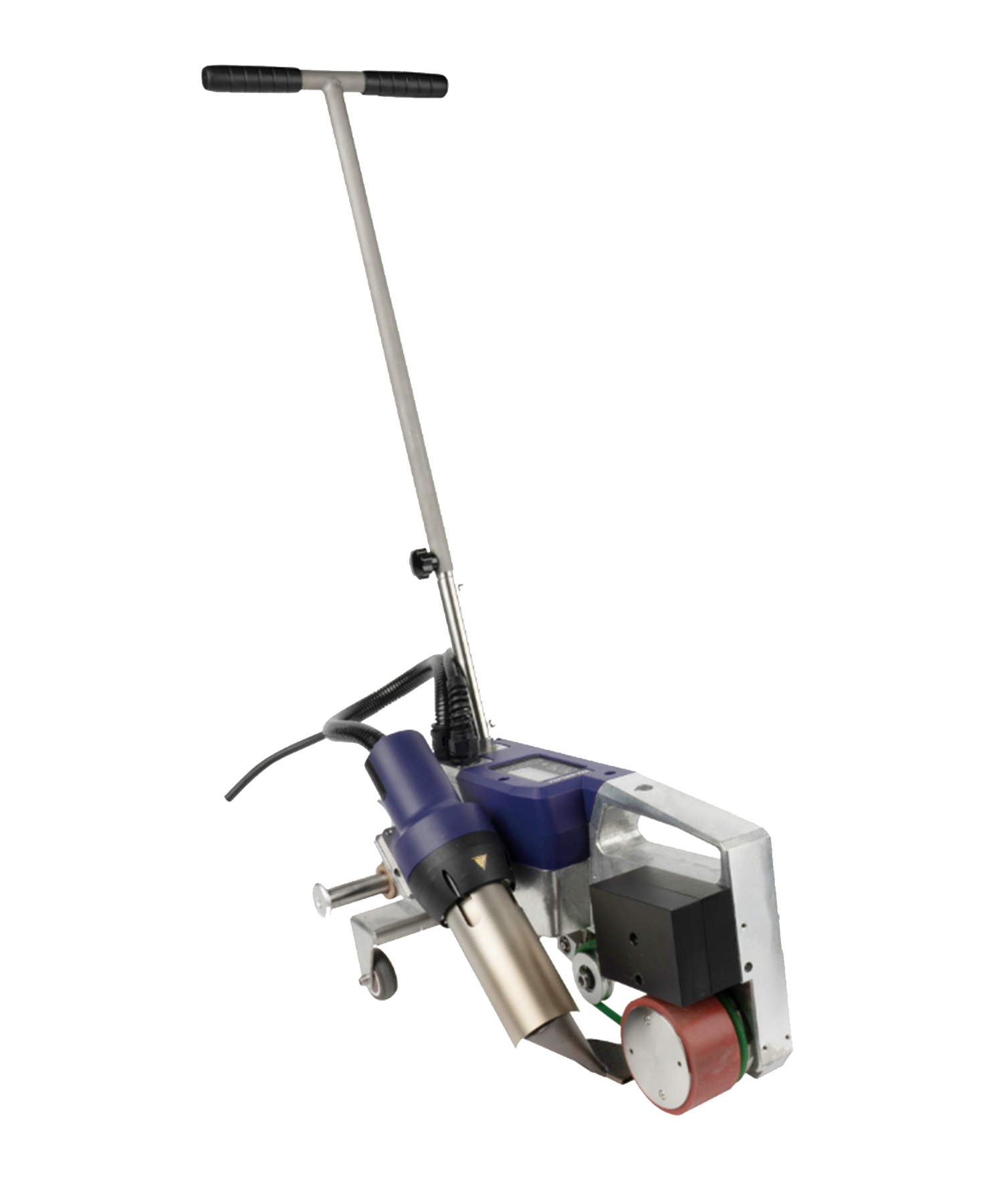

The RYH1600D Hand Extrusion Welder delivers professionalgrade results with its robust 1300W extruding motor and 3400W hot air system. This combination enables efficient welding of thick plastic materials (up to 30mm) at an impressive extrusion rate of 2.03.0 kg/h. The 800W welding rod heating system ensures consistent, highstrength welds that meet industrial standards.

Key Features:

Hightorque 1300W extruder motor for smooth material flow

3400W adjustable hot air system (50550°C) for optimal preheating

800W rod heater for stable welding performance

Ergonomic design for comfortable operation

Suitable for HDPE, PP, PVC, and PVDF materials

Industrial Applications:

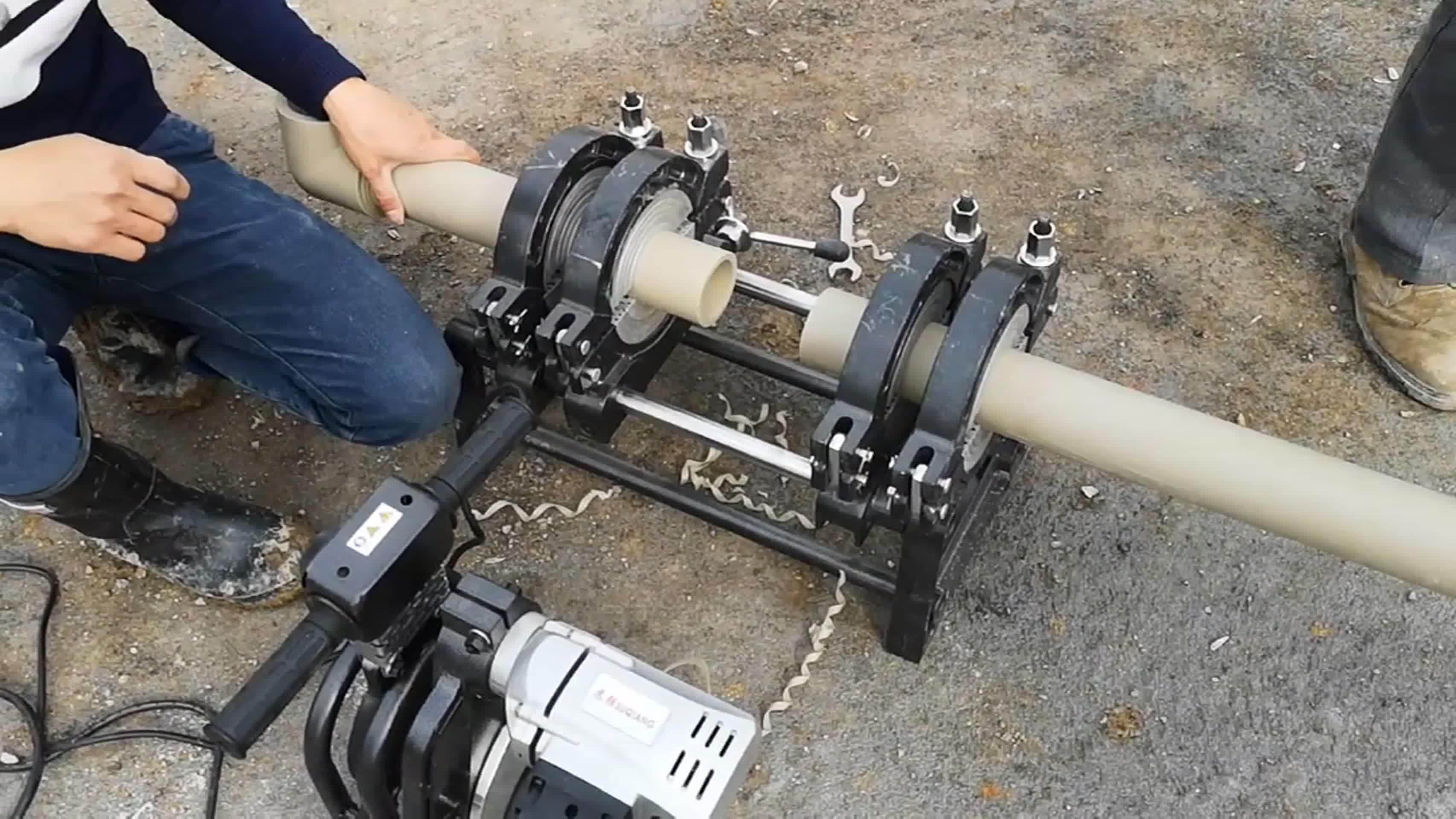

1. Pipeline Systems: Creates leakproof joints for water and chemical pipes

2. Storage Tanks: Provides durable repairs for industrial containers

3. Geomembrane Installation: Efficiently welds pond liners and landfill covers

4. Plastic Fabrication: Ideal for manufacturing and repair work

Operation Guide:

1. Prepare surfaces by cleaning with isopropyl alcohol

2. Preheat material edges to 300400°C (for HDPE)

3. Maintain consistent speed and pressure during welding

4. Inspect welds for uniform bead appearance

Maintenance Tips:

Clean nozzle after each use

Regularly inspect heating elements

Lubricate moving parts monthly

Store in dry conditions

Why Choose RYH1600D?

Faster than traditional hot air welding

Produces stronger joints than solvent methods

Reduces material waste with precise extrusion

Handles large projects efficiently

This professionalgrade welder is particularly valuable for:

✓ Industrial maintenance teams

✓ Plastic fabrication shops

✓ Environmental engineering projects

✓ Infrastructure repair crews

For optimal results, always follow manufacturer guidelines and wear appropriate PPE during operation. The RYH1600D's combination of power and precision makes it a reliable choice for demanding plastic welding applications.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.